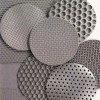

Composite Shaker Screens are engineered using high-quality 304 stainless steel, offering superior durability and performance. These screens are designed with multiple layers of wire cloth (typically 2 to 4), which are bonded together without the need for a steel backing plate. This construction enhances the effective filtering area, improving filtration efficiency while extending the service life of the shaker screen. The result is a more cost-effective solution that ensures reliable and long-lasting performance in demanding applications.

Composite Shaker Screens for Oil and Gas Industry Applications

Composite Shaker Screens are made with a strong composite frame and 2 to 3 layers of stainless steel wire cloth. The wire cloth can be bonded to the frame with a metal-rubber lining or directly attached, offering durability and flexibility. Each layer of the wire cloth has different mesh sizes to improve screening performance and achieve finer separation. The high-strength composite frame and tensioned wire cloth work together to handle higher flow rates and extend the screen's lifespan. The screens feature a quick tensioning system for easy installation, reducing downtime during replacements. Additionally, the wire cloth is divided into smaller sections to prevent local damage, ensuring better overall performance.