Product features:

High-temperature, long-term weather, no cracks, no tasteless, environmentally friendly, non-flammable, not friable, do not fade, resist the impact of strong, good toughness, high temperature, laser cutting, saw blade cutting, compression molding bending, Glue connection.

Main application:

Canopy, bus stop, taxi fence, advertising board. Advertising light boxes, plastic packaging, point of sale, store shelves, display panel, plate products, motorcycle windshield, the car windshield hat, vending machine panel, simple machining, cold bending, hot bending, plastic molding processing. Equipment casing.

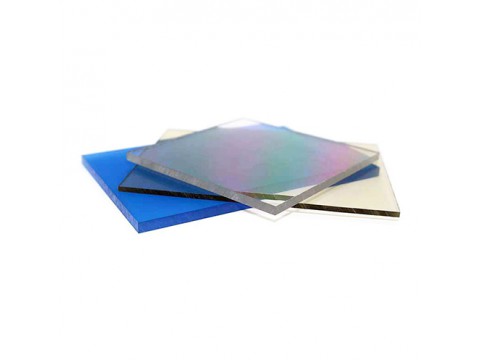

Common color:

Transparency / Lake-Blue /Grass-Green / Milk-White / Brown / Royal-Blue

Function details:

(1) Mechanical properties

1. the impact resistance strength: soild sheet with the impact resistance is very good with excellent impact resistance, it is 250 times higher than the traditional glass, Kubiak Ley sheet higher of 30 times. The hardend soild sheet with the impast resistance is named“transpart steel plate”

2. The tensile strength is good,the hardend soild sheet with the heat resistance is good.And the tensile strength is still up to 350kgf/cm2.

3. bending strength: plus hard endurance plate bending good, even though it’s 120 degress the bending angle of 90 degrees, still not broken.

4. anti fatigue and creep resistance: the hardness of the hardened plate is the best. Even if it’s at high temperatures, the creep is still small.

(2) Thermal performance

1. the melting temperature : The shape temperature of plus hard plate is 135 degress, its continuous use temperature is up to 120 degrees.

2. the coefficient of linear expansion : linear expansion coefficient of 7x10-5cm/cm/C. in the plastic is smaller.

3. brittle temperature: The brittle temperature plus hard board which is 40 centigrade below zero the lowest continuous use of temperature is 30 centigrade below zero.

4. combustion: hard endurance plate is one of the difficult to extinguish self extinguishing plastic, it will not produce toxic gases when heated at high temperature.

5. thermal conductivity: hard endurance plate thermal conductivity and general plastic little difference, is the glass 1/4, iron 1/300, aluminum 1/1000, copper 1/2000, is one of the excellent thermal insulation material.

(3) optical properties

1. light transmission: hard endurance plate transmittance of more than 85% and glass.

2. weather resistance: General PC endurance plate exposed to the outside for a long time, by UV irradiation easily lead to yellowing and surface degradation. Stiffened plate surface with one side UV protection, even if the long- term exposure to the outside, its optical and mechanical properties have no significant change.

(4) chemical resistance

The resistance of polycarbonate to weak acid, weak base and alcohol at room temperature is good, but the resistance to strong acid, benzene, chlorinated hydrocarbons and esters Poor performance, easy to produce dissolution, swelling or decomposition of the phenomenon. Because of its chemical resistance and temperature, the internal residual stress and violence The length of time is related, so special attention should be paid before use.